ENCE-PRODUCTS

Ence NCW Series Submersible Fan

Advantages of Ence submersible Roots blower:

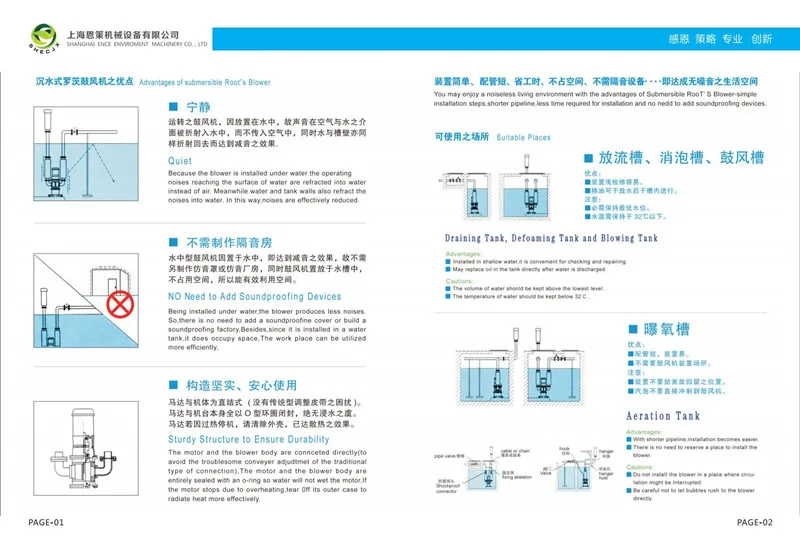

It is quiet, no need to build a soundproof room, and has a solid structure. Use with peace of mind. Simple structure and easy installation

Ence submersible Roots blower is widely used:

River ecological governance, integrated sewage treatment equipment, aquaculture, drainage channels, defoaming channels, blower channels, aeration channels, etc

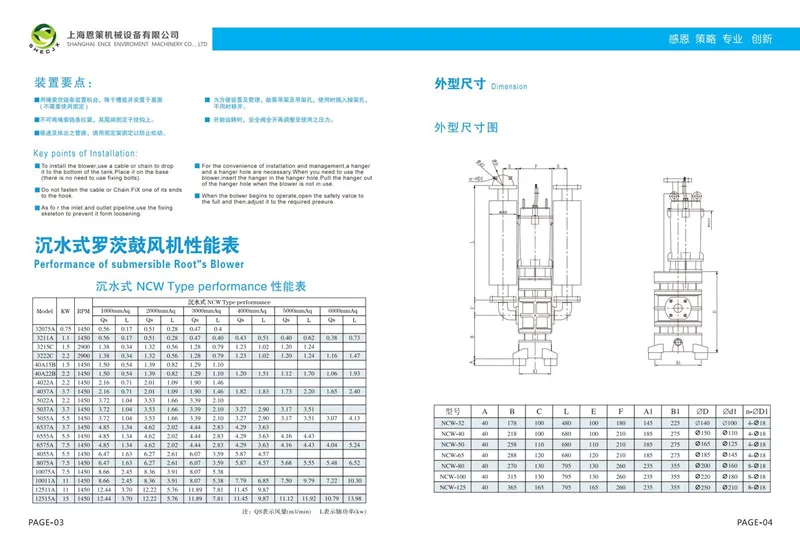

Parameters of Ence submersible Roots blower:

Flow rate: 0.38-12.44m ³ /min Pressure: 1000-6000mmAq Power: 0.75-15KW Diameter: 32-125mm

Advantages of Ence submersible Roots blower:

It is quiet, no need to build a soundproof room, and has a solid structure. Use with peace of mind. Simple structure and easy installation

Ence submersible Roots blower is widely used:

River ecological governance, integrated sewage treatment equipment, aquaculture, drainage channels, defoaming channels, blower channels, aeration channels, etc

Parameters of Ence submersible Roots blower:

Flow rate: 0.38-12.44m ³ /min Pressure: 1000-6000mmAq Power: 0.75-15KW Diameter: 32-125mm

- Details

- Parameter

The NCW submersible Roots blower is a high-performance and low-noise blower independently developed, designed and produced by Shanghai Ence Environmental Protection Equipment Co., LTD., which meets the current environmental protection requirements.

Advantages of the fan:

1. Lower energy consumption: As the submersible blower is submerged in water, the number of heat dissipation holes in the bearing housing is reduced, which correspondingly lowers pressure loss and enhances the overall efficiency of the machine.

2. Tranquility: When the blower is in operation, as it is placed in water, the sound is refracted into the water at the interface between air and water, and does not penetrate into the air. At the same time, the water and the tank

The wall also refracts back to achieve the effect of sound suppression.

3. No need to build a machine room: Since the submersible blower is placed in water, there is no need to build a separate machine room. At the same time, the blower is placed in the water tank, which does not occupy space. Therefore

So as to make effective use of the space.

4. Extended service life and extremely long maintenance cycle: As the fan is submerged in water, it has excellent heat dissipation, reducing the wear of internal vulnerable parts and thus extending its service life.

The maintenance cycle is two years.

5 Solid structure and safe to use: The motor and the body are directly connected (without the trouble of adjusting the belt in the traditional type). Both the motor and the machine itself are equipped with O-rings

Sealed tightly, there is absolutely no risk of water ingress. If the motor stops due to overheating, please clean the casing to achieve the effect of heat dissipation.

Working principle:

The NCW Ence brand submersible blower is derived from a Roots blower and is a Roots blower specially developed for sewage treatment that can be submerged underwater.

The fan adopts a direct-coupled structure. The rotor is of a closed non-contact type. The double-shaft parallel three-blade impeller has a small amplitude and a long bearing life, and does not require a pulley to drive the operation

"Forward. Submersible blowers are installed at the bottom of the water, with holes opened in the connecting pipelines for aeration. Sewage treatment is carried out through the aeration and reoxygenation method.

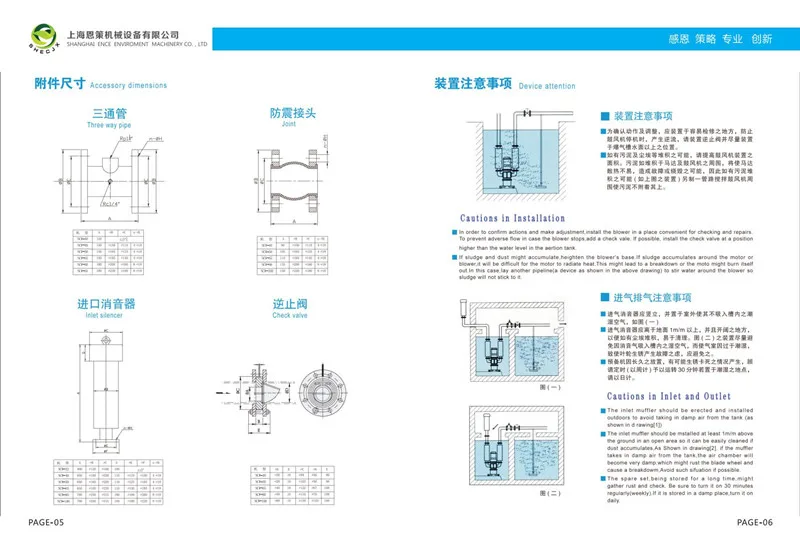

Installation method

Before installing the submersible blower, conduct an air tightness test on the extension pipe of the submersible blower first. After the test is completed, proceed with the following installation steps:

1. Connect the power supply and confirm the forward and reverse rotation of the machine.

2. Install two extension pipes for the inlet and outlet, and use sealing gaskets.

3. Conduct an air tightness test on the connection between the flange of the extension pipe and the flange of the submersible blower muffler.

4. Use a stainless steel chain to lift the submersible motor from the lifting ring and send the machine to the fan installation location.

5. Fix the base of the submersible blower and the extension pipe.

6. Install the inlet muffler and elbow.

7. Install the check valve and three-way valve.

8. Install the elastic joint and the main pipe of the fan.

9. Start up and conduct a trial run.